News

Achieving 50% Thermal Efficiency of Car Engines - Reducing Carbon Dioxide Emission through SIP's All-Japan Consortium Updated in March 2019

A technology that allows better thermal efficiency for car engines has been developed. The thermal efficiency exceeded 50%, a 10-point increase compared to the present figure. It is the result of tight all-Japan multi-industry multi-academia collaboration initiated as part of the Cross-ministerial Strategic Innovation Promotion Program (SIP). Many Japanese universities, including Keio University, Kyoto University, University of Tokyo, Waseda University, automobile manufacturers and national institutes took part in this project. If automakers should incorporate this technology to mass-produced cars, it will improve fuel efficiency, decrease carbon dioxide and greenhouse gas emissions. This result was presented on January 28 at SIP's open symposium on Innovative Combustion Technology.

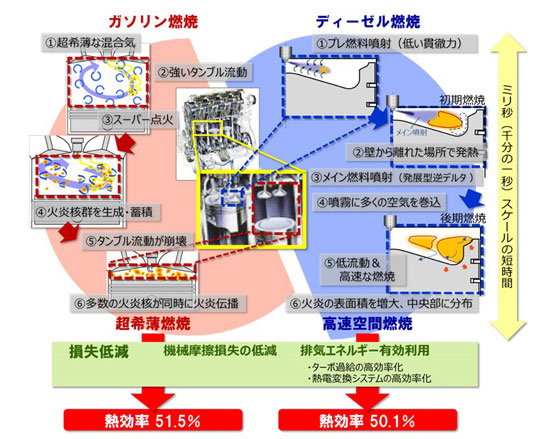

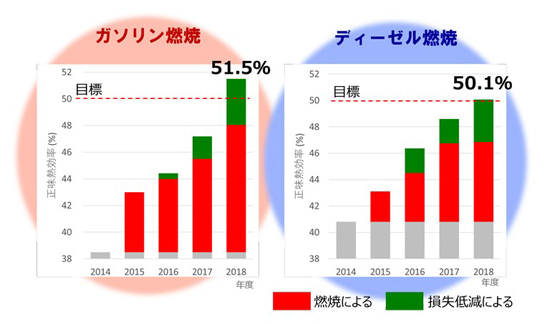

Engine thermal efficiency is the rate of converting total fuel energy to engine work. The project achieved 51.5% for gasoline engines and 50.1% for diesel engines. For gasoline engines, the project succeeded in developing a technology called “super-lean burn” which enables low-temperature combustion with reduced energy-loss. For diesel engines, the project came up with the high-speed combustion technology. This can occur when sprays of fuel mix with air and are dispersed optimally. For both gasoline and diesel engines, relevant new technologies were integrated to achieve better thermal efficiency.

Although electrification of the car engine is becoming a worldwide trend, the SIP presentation estimates that 90% of all cars in the world would still be equipped with internal combustion engines for gasoline or for diesel fuels in the next 20 years. The current thermal efficiency of an automobile engine is about 40%. In the past 40 years since the 1970s, thermal efficiency only rose by 10 points. The breakthrough result obtained through this SIP scheme shall be shared by Japanese car manufacturers who participated in this project. Manufacturers will optimize these results to apply them to their car designs and actual production.

As a national framework, SIP was adopted by the Prime Minister's Cabinet in June 2013 to evoke innovation from basic research to practical application/commercialization. Japan Science and Technology Agency (JST) is the administrative body which manages each project. JST selects important agendas and appoints a Program Director (PD) for each project. In the first batch of SIP, there were 11 projects. The Innovative Combustion Technology project started in FY2014 with Mr. Masanori Sugiyama (Toyota Motor) as the Program Director. It was a nationwide project where many universities and research institutes contributed in different capacities. This project was supported by the Research Association of Automotive Internal Combustion Engines (AICE), which consists of 9 Japanese auto manufacturers, plus the National Institute of Advanced Industrial Science and Technology (AIST) and Japan Automobile Research Institute (JARI).

Reference

https://www8.cao.go.jp/cstp/panhu/sip_english/10-13.pdf

Red sections of the bars show efficiency in view of combustion while green sections of the bars show efficiency by decreased energy-loss (Provided by JST/Cabinet Office SIP Secretariat)